Design to Production

New Paragraph

We work with you to come up with the very best solutions for your challenges!

01

Introduction & Design Brief

Identify and clearly define the problem or opportunity that the design aims to address. Address the needs, goals, and constraints of the project.

02

Research & Ideation

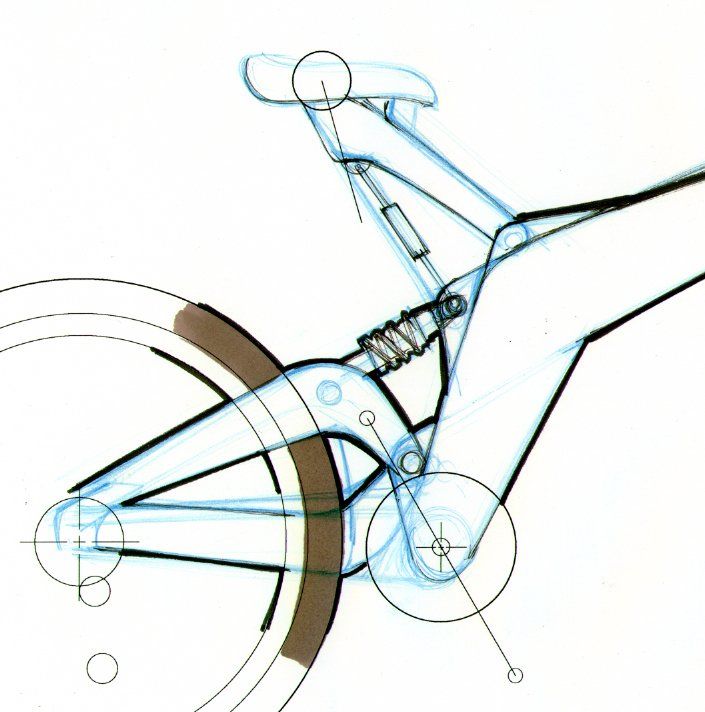

Review existing product solutions and market trends. Generate concept ideas through brainstorming sessions, mind mapping, collaborative discussions and preliminary sketches.

03

Concept Development & Detail Design

Develop detailed concepts, including preliminary CAD layouts and where applicable, initial models or prototypes. Review and shortlist concepts that align with the project

brief and client goals.

04

Prototype & Testing

Fabricate a part or full prototype of the selected concept to test functionality and assess form and ergonomics. Samples may be used to seek feedback from potential users. Adjust design and refine as agreed.

05

Production Documentation

Create detailed production documentation, including CAD files, drawing specifications, and other material and component information as necessary.

06

Production Process Implementation

Collaborate as required with manufacturing teams and other suppliers. Evaluate the performance of first production and liaise with suppliers to optimise details as required.

On-Site Rapid Prototyping

Our state-of-the-art studio facilities have an on-site prototype workshop with a range of in-house 3D printers. This allows us to rapidly create prototypes for design optimisation and pre-production evaluation. For many clients this capability eliminates concerns around third party supplier delays and potential intellectual property issues. We can also produce customised prototypes suitable for marketing or market research purposes. With our on-site workshop and in-house 3D printers we can provide you with a complete product development service from concept to mass production.

Slide title

Write your caption hereButton

At Nielsen Design we have a process that guarantees elegant design solutions every time. Our designers start with a product brief and develop design solutions in collaboration with the client. This process typically involves sketches, product renderings, CAD models, 3D printed samples, working prototypes and detailed specifications for production. We’re happy to work with your existing suppliers or our extensive industry contacts to help ensure a smooth transition to production. At all times our services are tailored to fit with your requirements and provide the best possible outcomes.

Our Design to Production Process

1. Introduction and Design Brief:

Identify and clearly define the problem or opportunity that the design aims to address.

Address the needs, goals, and constraints of the project.

2. Research and Ideation:

Review existing product solutions and market trends. Generate concept ideas through

brainstorming sessions, mind mapping, collaborative discussions and preliminary

sketches.

3. Concept Development and Detail Design:

Develop detailed concepts, including preliminary CAD layouts and where applicable,

initial models or prototypes. Review and shortlist concepts that align with the project

brief and client goals.

4. Prototype and Testing:

Fabricate a part or full prototype of the selected concept to test functionality and

assess form and ergonomics. Samples may be used to seek feedback from potential

users. Adjust design and refine as agreed.

5. Production Documentation:

Create detailed production documentation, including CAD files, drawing specifications,

and other material and component information as necessary.

6. Production Process Implementation:

Collaborate as required with manufacturing teams and other suppliers. Evaluate the

performance of first production and liaise with suppliers to optimise details as required.